- Home

- Brass Products

- Manifold

Brass Manifold

The manifolds are generally made of CW617N or CU57-3 brass. We also use CW602N brass, CW625N brass, CW725N brass, etc., as the raw materials for manifolds body and internal parts such as balls and spindles. Various surface treatments can be offered according to customers' requirements, such as nickel plating and polished chrome plating. All of our manifolds are forged and formed with a thickness of 3 mm-4 mm, which can prevent the leakage of water.

The manifolds and spindles are both processed by CNC machines, so the spindles can precisely match with the manifolds. At the same time, high temperature and wear resistant EPDM material is adopted to make the sealing rings to guarantee a long service life. Our regular sizes are 3/4" and 1", and the three different threads are 16 mm x 1/2", 22 mm x 18 mm and 24" x 19 mm.

In order to ensure the leakproofness of the product, every single manifold will be tested by using water pressure machine before sending to customers. Endurance tests for manifold are also done frequently to make sure the products can be “open-close” for minimum 10,000 times.

Shown here are products we currently have in stock, and we offer customization services in terms of shape, material, weight, and size.

-

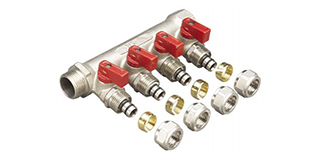

- Manifold, Brass Color

-

Model:

VF-0803-

Specification:

1" x G1/2"-5

1" x G1/2"-4

1" x G1/2"-3

1" x G1/2"-2

-

- Manifold, Nickel Plated, Plastic Handle

-

Model:

VF-0804-

Specification:

1" x G1/2"-5

1" x G1/2"-4

1" x G1/2"-3

1" x G1/2"-2

-

- Manifold, Nickel Plated, Plastic Handle

-

Model:

VF-0805-

Specification:

1" x G1/2"-5

1" x G1/2"-4

1" x G1/2"-3

1" x G1/2"-2

-

- Manifold, Nickel Plated, Plastic Handle

-

Model:

VF-0808A-

Specification:

3/4" x G1/2"-5

3/4" x G1/2"-4

3/4" x G1/2"-3

3/4" x G1/2"-2

1" x G1/2"-5

1" x G1/2"-4

1" x G1/2"-3

1" x G1/2"-2

-

- Manifold, Nickel Plated, Plastic Handle

-

Model:

VF-0809A-

Specification:

3/4" x G1/2"-4

3/4" x G1/2"-3

3/4" x G1/2"-2

-

- Manifold, Nickel Plated, Plastic Handle

-

Model:

VF-0810-

Specification:

1”× 1/2'' x 2way

1”× 1/2'' x 3way

1”× 1/2'' x 4way

1”×1/2'' x 5way

-

- Manifold, Nickel Plated, Plastic Handle

-

Model:

VF-0811-

Specification:

1" x G1/2"-5

1" x G1/2"-4

1" x G1/2"-3

1" x G1/2"-2

-

- Bar Manifold, Brass Color

-

Model:

VF-0814-

Specification:

1" x 1/2" x 3way

1" x 1/2" x 4way

3/4" x 1/2" x 3way

-

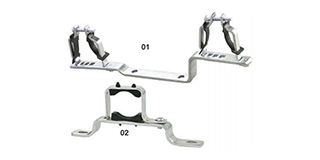

- Bracket, Iron

-

Model:

VF-0815A/B

-

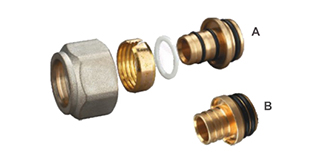

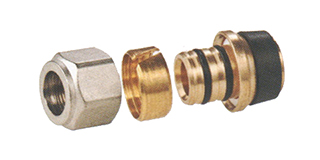

- Connector for Al-PEX

-

Model:

VF-0816A-

Specification:

16 x 1/2" x 2.0

-

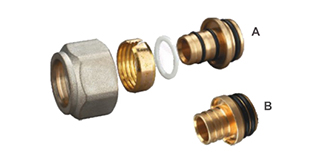

- Connector for PEX

-

Model:

VF-0816B-

Specification:

16 x 1/2" x 2.2

16 x 1/2" x 2.0

-

- Connector for Al-pex

-

Model:

VF-0816D-

Specification:

24×19-18×2.0

24×19-18×2.5

24×19-16×2.0

Vandf has more than 20 years of experience in the production of brass valves and brass fittings.

With two factories and more than 200 workers, we can not only provide quality brass products, but also fulfill large-quantity orders.

- Add.:

Chengxi Street, Taizhou City, Zhejiang Province - Mail: jason.xu@vandfglobal.com

- Contact: Jason Xu

- Mobile: +86-13968574909

- Whatsapp: +86 13968574909

- Wechat: 13968574909