- Home

- Factory Tour

With over 20 years of experience in the production of brass valves and fittings, Vandf has two factories with more than 200 workers to provide customers with large-quantity orders while maximizing quality at the same time.

- Raw materials

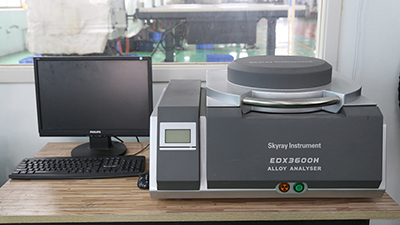

The raw material of brass rods is generally CW617N that meets the European standards. We are equipped with a German brand spectrometer to accurately measure the content of various elements of the brass rods to ensure they meet our production standards.

Three smelting furnaces are used to achieve a daily output of around 55 tons of brass rods.

- Forging production

We have 30 forging machines between our two plants. Our brass valves and fittings are specially forged to maximize their bearing capacity, which can realize high production efficiency while minimizing the waste of raw materials. We have good control over production costs so as to offer affordable prices for customers.

- CNC machining

Equipped with CNC lathes, machining centers and 15 custom-made machines for thread cutting and rolling, we can achieve a machining precision of ±0.02 mm.Also, we spend 20% of our annual net revenue to update our machines every year.

- Automatic production

We have 11 automatic brass rod feeders, 12 pieces of fully automatic processing equipment, as well as a number of automatic assembly machines, etc.

Automatic production allows us to maximize efficiency while we also minimize our labor costs so that we can offer products to customers at competitive prices.

- Inspection

We carry out strict inspections prior to warehousing raw materials. Each batch of purchased materials is only accepted if it comes with a material analysis report. Unqualified materials will not be placed in storage. Meanwhile, we conduct random inspections on materials to ensure that the brass materials meet our standards.

70-80% of the workers in our factory are skilled workers with more than 10 years of operating experience. They are also specially trained to control the quality of products. Also, every 12th machine is periodically inspected by a quality inspector to ensure product quality.

Equipped with a variety of testing equipment, such as air pressure testing machines and hydraulic testing machines, we will conduct final inspection on each product before delivery to ensure only qualified products are delivered to customers.

- Mold warehouse

Our mold warehouse stores a large number of product molds we have previously manufactured. Over the past 20 years of production, we have designed and created thousands of valves and fittings molds with different specifications. Therefore, we are confident in our abilities to meet the demands of customers by offering a complete range of brass valves and fittings.

- video

- Add.:

Chengxi Street, Taizhou City, Zhejiang Province - Mail: jason.xu@vandfglobal.com

- Contact: Jason Xu

- Mobile: +86-13968574909

- Whatsapp: +86 13968574909

- Wechat: 13968574909